- Company

- Products

- All

- VACUUM FEEDING SYSTEM SINGLE SCREW EXTRUDER

- PET BOTTLE HOT WASHING COMPLETELY RECYCLING LINE

- PP/PE WASHING COMPLETELY RECYCLING LINE

- PLASTIC EXTRUSION-PELLETIZING MACHINE

- DEHUMIDIFY-DRYING / CRYSTALLIZING / MIXING

- SHEET EXTRUSION MACHINE

- PP/PS HANGER MATERIAL WASHING, SEPARATION RECYCLING LINE

- THE CUT FIBER-PA6, PA66 FROM CARPET- WASHING, SQUEEZING-DRYING, EXTRUSION-PELLETIZING COMPLETELY RECYCLING LINE

- PA FISH NET, WASTE YARN WASHING COMPLETELY RECYCLING LINE

- SHREDDER / CRUSHER / CUTTING MACHINE

- RECYCLING, SORTING & INSPECTION MACHINE

- WASHING / SEPERATION / DRYING / LABEL BLOWING / WEIGHTING

- SLIM CABLE/WIRE RECYCLING-PLASTIC AND COPPER SEPARATION PLANT

- WASTE WATER FILTRATION SYSTEM

- PLASTIC TESTING INSTRUMENT

- Video

- E-catalogue

- News

- Contact Us

- Home/

- Products/

- VACUUM FEEDING SYSTEM SINGLE SCREW EXTRUDER/

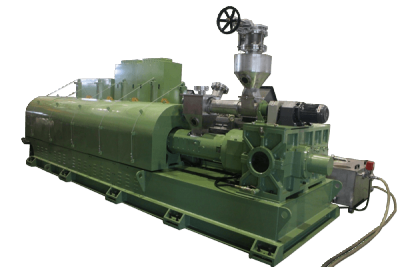

- VACUUM FEEDING SYSTEM SINGLE SCREW EXTRUDER

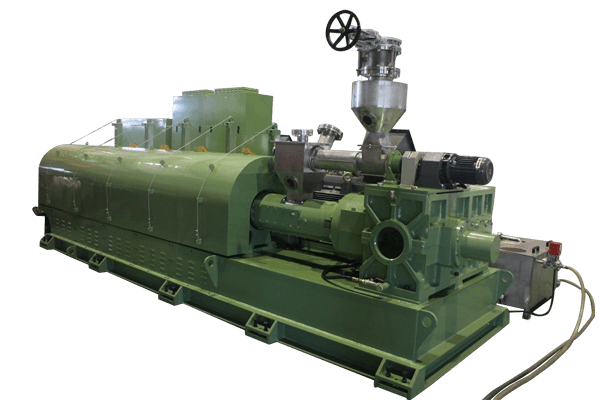

VACUUM FEEDING SYSTEM SINGLE SCREW EXTRUDER

Feature:

A well-known group in Taiwan, they installed KOWIn vacuum feeding system single screw extruder to replace their original Austrian and German extruder during past 10 years. They have already more than 20 sets of KOWIn vacuum feeding system single screw extruder.。

KOWIn vacuum feeding system single screw extruder, it can be used for processing polymers and producing products, as well as recycling.

Available processing polymer materials:

standard polymers such as PET, PA, PP and PE

Available recycling polymer materials:

PET material and flake, PE, PP- flake of film & bag

Even the special polymers such as PLA and PBT can be processed by KOWIn vacuum feeding system single screw extruder

Advantages of core competitiveness:

When the polymer is processed and produced, it is easy to cause carbon dioxide to enter the polymer due to the air or water vapor in the resin or recycled materials during extruding, resulting in polymer degradation, yellowing, bubbles… etc, caused product quality declines.

Through the past deeply experiences, KOWIn specially developed the vacuum feeding system single screw extruder, to solve the problem for the manufacturing industry.

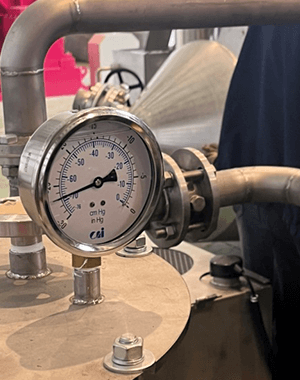

When the polymer is fed, the air is evacuated to be a vacuum form. Once the polymer enters the extruder, the water vapor remaining in the polymer is extracted and discharged by vacuum. Reduce yellowing, IV drop, and improve the manufacturing quality.

For PET polymers, the IV is reduced within 3% during extruding.

Advantage:

1.Reduce yellowing, IV drop, and improve material quality.

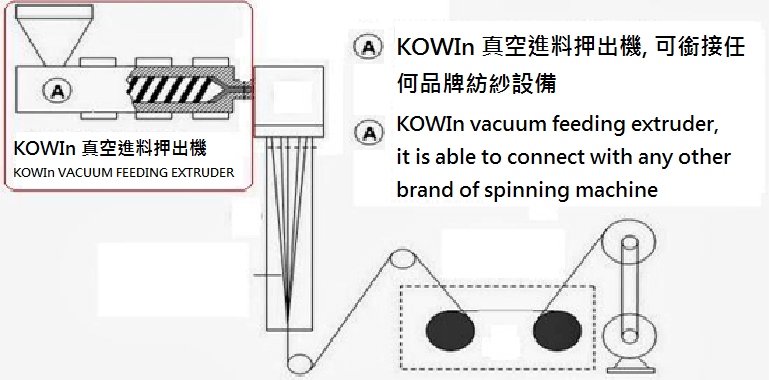

2.Can be connected to any brand of spinning machines or other production machines.

3.High-standard screw design and manufacturing, low temperature and high output design, the polymer is extruded by balanced pressure to obtain high-efficiency output. The necessary energy obtained by the motor, cooperate with the heat preservation design, it can save electricity and energy.

4.Efficiency during polymers feeding at vacuum:

5.KOWIn vacuum feeding system single screw extruder, using for Spinning extruding:

Applications:

1. Spinning extruding

2. Sheet extruding

3. Film extruding

4. Co-extruding

5. Recycling

And various special application extruding

Specifications of KOWIn vacuum feeding system single screw extruder

| Model no. | SCREW DIA. | Capacity | Motor | Electric |

|---|---|---|---|---|

| KOWIN-240A | Φ105mm | 4 TON/DAY | 150HP (110KW) | 76KW |

| KOWIN-250A | Φ120mm | 7 TON/DAY | 175HP (131.25KW) | 88KW |

| KOWIN-260A | Φ135mm | 10 TON/DAY | 250HP (187.5KW) | 122KW |

| KOWIN-270A | Φ150mm | 15 TON/DAY | 300HP (225KW) | 105KW |

| KOWIN-280A | Φ165mm | 20 TON/DAY | 450HP (337.5KW) | 112.8KW |

| KOWIN-290A | Φ180mm | 30 TON/DAY | 600HP (450KW) | 138KW |

Calculation by PET Polymer, Capacity is changed due to material feature

We can design and manufacture the screw and barrel of this vacuum feeding polymer extrusion machine according to customer needs. Welcome to contact us.

* :Required Field

VACUUM FEEDING SYSTEM SINGLE SCREW EXTRUDER

Product Name : VACUUM FEEDING SYSTEM SINGLE SCREW EXTRUDER

True display, express sincerely

- KO WIN YANG INDUSTRIAL CO., LTD.

-

+886-4-26300869

Copyright © KO WIN YANG INDUSTRIAL CO., LTD.